PRODUCTS

LHD FIRE GRILLES

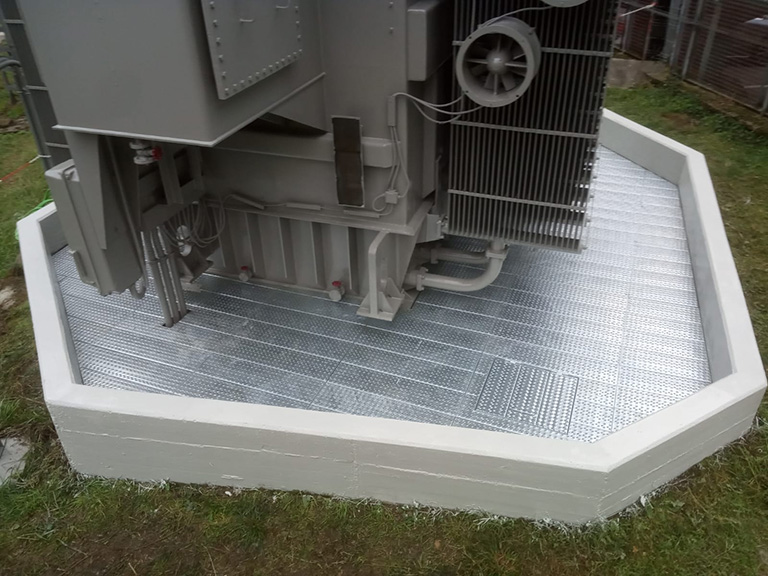

LHD ® fire protection solutions for oil-filled electrical transformer station floors.

Safety grilles with fire-retardant properties, designed for a variety of essential applications. These grids are especially effective for covering electrical transformer pits or serving as thermal protection covers on off-shore platforms. The LHD® safety grating has been subjected to tests that demonstrate its ability to extinguish mineral oil fires at transformer stations in just 6 seconds, in addition to resisting the generation of extreme heat in flame towers on oil and gas platforms.

With a solid track record that spans more than three decades and includes the execution of more than 1,000 projects, PcP has perfected the production of fire grates, consolidating itself as a leader in the European market.

The transformer station seeks to ensure the safe distribution of electrical energy to the grid. The risk of fire from transformer oil leaks is a critical safety and environmental issue. Therefore, the design of the pit is crucial, usually constructed of concrete to capture and quickly evacuate oil in case of leaks. It is essential that the oil can drain through the metal surface covering the pit as quickly as possible (600 liters per m2 per minute).

European substations have diverse designs, although the requirements and criteria are the same. Some use stones in the pits, supported by tramex grates to manage oil leaks, but this limits the capacity of the pit and makes inspection difficult. Others prefer loose panels, apparently cheaper, although this implies additional costs due to the long installation time and the risk of promoting the presence of oxygen, complicating fire extinguishing.

In order to ensure maximum safety, PcP has developed a cost-effective solution that requires little or no maintenance and requires a smaller pit, while complying with all regulations. These grids are especially useful for covering electrical transformer pits or acting as thermal protection covers on off-shore platforms.

PcP LHD® safety grilles are welded together to minimize airflow, offering excellent drainage and ensuring the extinction of oil fires in transformer stations in just 6 seconds, in addition to resisting the generation of extreme heat in towers of flames on oil and gas platforms.

These grates are easily replaceable and each solution is customized to meet specific safety requirements and design criteria.

PcP LHD® gratings, which include angle profiles and screws, are easily mounted into concrete, offering R11 level slip resistance and high load capacity to provide maximum safety for those working in transformer substations.

This product has been tested and approved by the Swedish testing institute RISE for its fire extinguishing and oil drainage properties, making it the ideal choice for transformer stations and oil platforms on land and at sea.

- PTV slip resistance index: 36+ Low Slip Potential

- Average PTV value in dry conditions: 91

- Average PTV value in wet conditions: 55

- Anti-slip classification: R11 = 27° > slope > 19° according to DIN 51130 regulations

- Spacing: V10 according to DIN 51130 regulations

- Free area: Between 2.4% and 3.7%

- Diameter of flared holes: 6 mm

- Drainage holes diameter: 6mm

- Distance between hole centers: 72 x 36 mm

- Meets the requirements of the sphere: 15, 20, 35 mm according to EN ISO 14122-2

Made in Denmark and 100% recyclable, the LHD® fire protection grating transforms transformer stations into considerably safer environments. Since the 1980s, PcP has been a pioneer in the design, development and manufacturing of safe fire protection solutions for off-shore oil and gas extraction platforms.

PcP products and solutions, including LHD®, are environmentally friendly, durable and made with 100% recyclable material. Designed to extinguish fires in just 6 seconds, the LHD® is positioned as one of the safest solutions available on the market.