PRODUCTS

ANTI-VIBRATORY SYSTEMS

Trafoflex® anti-vibration systems for transformers come in two types of products:

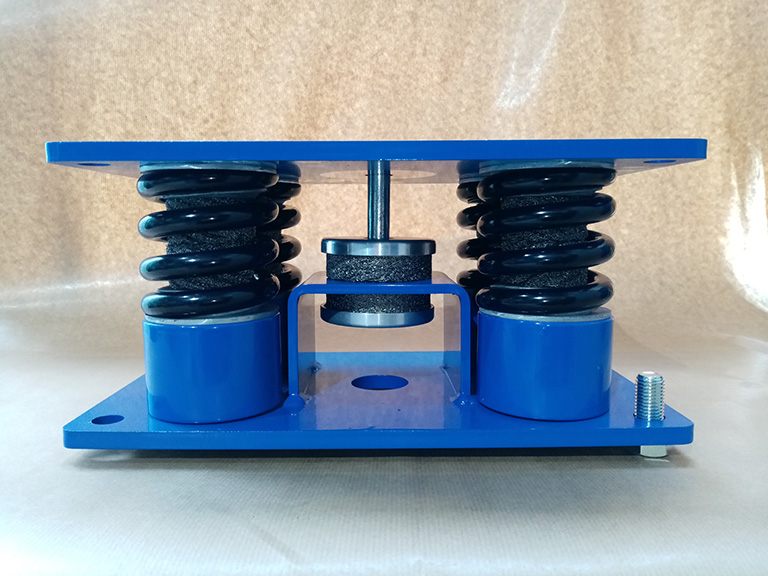

Anti-vibration mounts for transformers, they receive the machine wheel and are fixed to the ground either supported directly or by means of poles. Designed for low frequency vibrations, up to 3 Hz, these dampers are ideal for transformer suspension. They excel in environments with handling difficulties, eliminating more than 99% of structural noise. Completely metal, they can be used outdoors or in adverse environmental conditions.

Shock-absorbing springs for transformer, directly support the machine and are fixed to the ground with great stability. They stand out for their dual function as high-resistance springs and anti-vibration devices, specially designed for static electrical machines. These shock absorbers have excellent performance in absorbing vibrations, providing great robustness and durability. Approved by Endesa, they eliminate 99% of the main frequencies of vibrations emitted by the machine.

TRAFOFLEX® vibration dampers for transformers with wheel support

They offer an effective solution for isolating vibrations, noise and shocks. Specifically designed for low (LV), medium (MT) and high voltage (HT) static electrical machines, these anti-vibrators stand out for their exceptional performance, robustness and durability. Always at the forefront of anti-vibration systems, the best technology adapted to various powers and weights in electrical transformers is applied in its manufacturing.

These anti-vibrators, intended to receive the wheel of the machine, can be easily secured to the ground by means of supports or poles, providing a stable fixation. The damping element can adopt two configurations of silent blocks: a high-resistance transformer spring damped with a stainless metal cushion, or damped with vulcanized anti-vibration rubber.

This line of shock absorbers consists of two steel soles, two high-resistance metal springs, light alloy connection washers and a stainless steel wire metal cushion on each spring. With an external protection plate that prevents intrusions of materials that could stiffen the shock absorber, all external steel parts are protected with electrolytic zinc plating or painting. These elements, easy to assemble, adapt to the needs of the team with efficiency and precision.

Designed specifically for transformers, these anti-vibrators eliminate structural noise with greater than 99% isolation of the main vibration frequencies of electrical transformers. Operating effectively at low frequencies, down to 3 Hz, they are ideal for transformer suspension in challenging environments where handling is difficult. Completely metallic, they can be used outdoors or in adverse environmental conditions, without creep (loss of height over time), which guarantees a useful life equivalent to or greater than that of the transformer they insulate, without the need for maintenance.

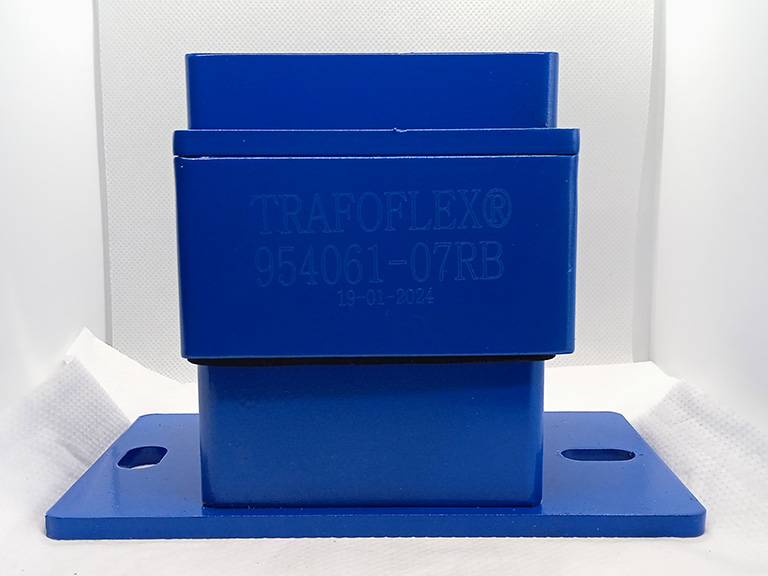

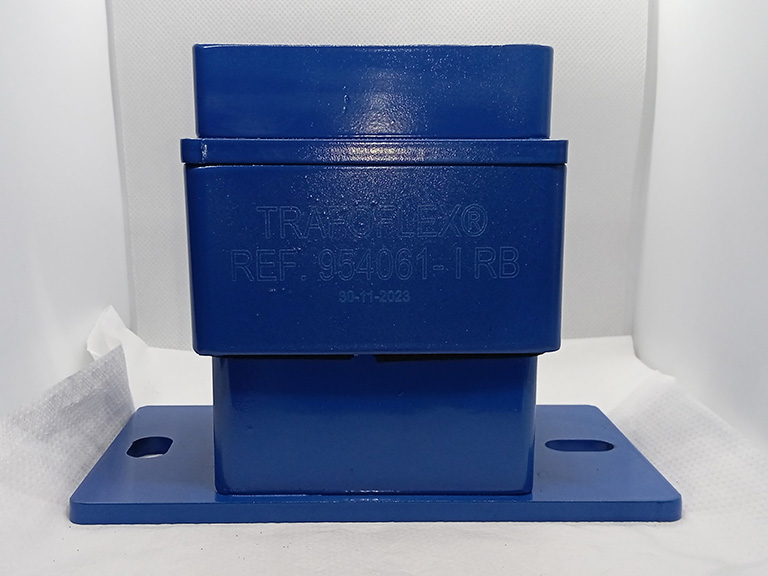

TRAFOFLEX® shock absorber springs for transformer

TRAFOFLEX shock absorber springs for transformers represent the cutting edge in design and manufacturing, due to their constant commitment to incorporating the most advanced technology on the market. They perform a double function, as high resistance springs and anti-vibration devices, being specially designed for static electric machines. They stand out for their exceptional ability to isolate vibrations, providing outstanding robustness and durability.

The genesis of vibrations in a transformer is attributed to the magnetostriction between the core plates, which undergo shape changes in the presence of the magnetic field. The main frequency of these vibrations is around 100 Hz, accompanied by its harmonics, although occasionally 50 Hz can also be significant. If these vibrations are not properly isolated, they spread throughout the building structure, generating annoying sources of noise. Specifically designed for transformers, our low frequency silent blocks – between 5 and 6 Hz natural frequency – effectively absorb the most common frequencies and are easily adapted to isolate other atypical frequencies. The quality of these products has been approved by Endesa, and they are calculated to achieve exceptional anti-vibration performance, isolating even more than 99% of the vibrations generated by electrical transformers.

Shock absorber springs for transformers not only provide structural support to the machinery, but are also anchored to the ground with great stability. Its anti-vibration component incorporates high-resistance metal springs that house metal cushion stops, made of shaped and pressed stainless steel wire.

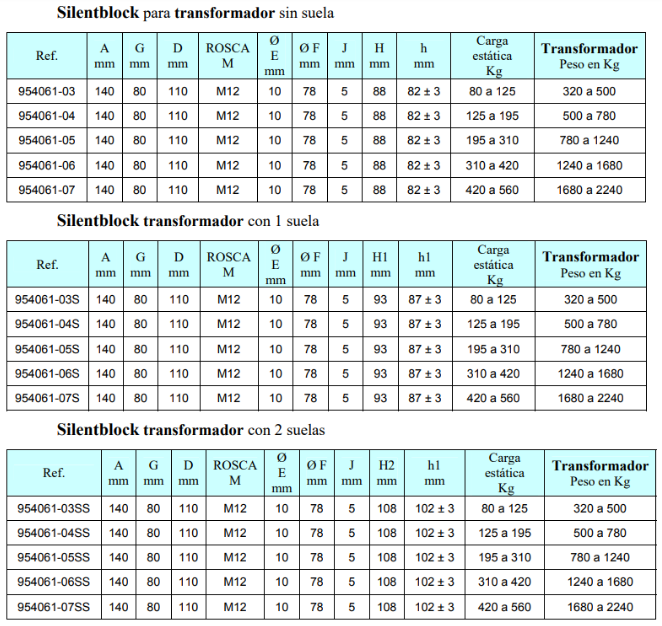

This line of shock absorber springs includes silent blocks formed by a single block or sets of silent blocks with high-resistance metal springs. Each block contains an internal silentblock made with metal cushions of stainless steel thread. Fixing to the floor is achieved using M12 threaded holes through fixing washers, allowing the possibility of adjusting the measurement according to the customer’s needs. Individual silent blocks can be supplied without sole, with one sole, or even with two soles, to be fixed using two through holes. The sole can be adapted according to the client’s specifications. To ensure durability, all steel parts are protected against corrosion by applying epoxy to the spring and painting or galvanizing to the fixing plates.

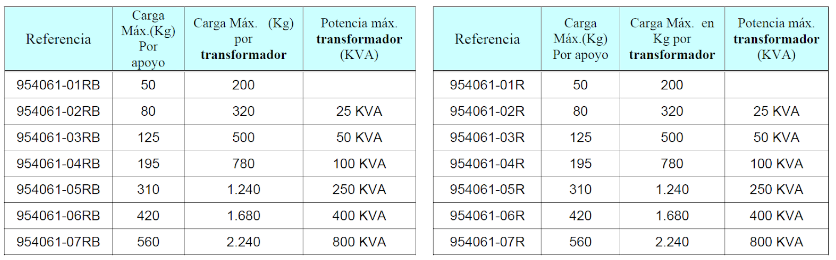

TRAFOFLEX ® anti-vibration range

TRAFOFLEX® shock absorber spring range

The silent block, an anti-vibration component used to mitigate vibrations, has evolved from its origin in the automotive industry to cover various industrial sectors, including the military field. Currently, catalogs offer variants that include stainless steel wire shock absorbers, expanding the options beyond traditional elastomers. This component allows the absorption of vibrations and shocks, helping to eliminate noises associated with mechanical impacts on the support structure.

The metal suspension, a type of anti-vibration support composed exclusively of metal elements, eliminates shocks and vibrations, achieving smooth and efficient operation of the supported equipment. Compared to rubber-based suspensions, metal suspension offers advantages such as high durability, resistance to adverse weather conditions and chemicals, stability against load variations and an economical option.

Elastic couplings, also known as anti-vibration couplings, address problems such as vibration damping, correcting misalignments and differences between shafts, allowing lighter constructions with higher tolerances. These couplings consist of two “manchones” that are hooked to the shafts to be coupled, with a flexible element acting as a vibration damper.

In the industrial field, anti-vibration mounts are defined as devices located between equipment and a supporting base, responsible for filtering, damping, dissipating and eliminating mechanical vibrations during operation. They can be composed of rubber as a damping element and metal as a supporting element, or be based entirely on metal, as is the case with the metal anti-vibration cushion. Concrete examples include elastic rubber-metal suspensions, 100% metal suspensions, and elastic couplings used as anti-vibration mounts.